Measure it, Manage it

“If you can’t measure it, you can’t manage it,” says highly respected business consultant, Peter Drucker. It’s widely accepted that knowledge is power. When we speak about knowledge, what we really mean is data. If you have data that shows you exactly what’s happening in your business- day-by-day, hour-by-hour, and minute-by-minute- you have the power to spot problems, address them and prime your business for ultimate profitability. In today’s technologically- advanced environment, dairy farmers have access to a solution that will gather and analyze parlor data so it can be turned into profit.

In this blog, we focus on Afimilk’s MPC – a highly advanced milking point controller that collects minute-by-minute parlor data that can be used to evaluate existing milking protocols, spot inefficiencies, and remediate issues.

Introducing the Afimilk MPC and AfiFarm Milking Efficiency Module

Afimilk’s MPC removes the need for human presence in the parlor to monitor milker activity by collecting detailed data on the following parameters:

Cluster attachment – How many times the milking cluster was attached in a session, whether restless cows caused any kick-offs, and how many times (if any) the equipment had to be reattached.

Flow rate – How long after cluster attachment milk flow began and the rate and volume of the milk flow, measured in 15-second increments during the critical first 2 minutes of milking.

Milking curve – A snapshot view of the entire milking output in the form of a graph called the “milking curve.” A quick glance at the milking curve will immediately show you if there is a problem with the output (more on this below).

Milking time – How long milking took overall, at what point in the milk flow session cluster detachment occurred, and more.

Pulsation & stimulation – The MPC optimally controls pulsation and stimulation. You can compare milk flow between shifts and see from the milk curve whether udder prep was optimized for the session. You can also access and change settings based on these results to get the most out of every session.

Taking the Data Further

Once you have gathered the data, you can use it to:

Automate processes – Preset your milking system to automatically comply with your desired protocol. For example, you can preset the maximum milking length for each session and specify at what flow volume detachment should occur. Not only will presets enhance your parlor’s efficiency, but they will also help you to ensure the best possible udder health for the cows because over- milked cows suffer from teat damage which can lead to udder infections and a high somatic cell count (SCC) – an important indicator of udder health in dairy cows.

See how you measure up – To evaluate how well you are doing, you can compare the parameters measured by your MPC to industry standards. For example, industry standards dictate that at least 50% or more of the total milk produced in a session should be harvested in the first two minutes of milking. If your cows are producing at a slower rate than this, you likely have a problem.

The Milk Flow Graph

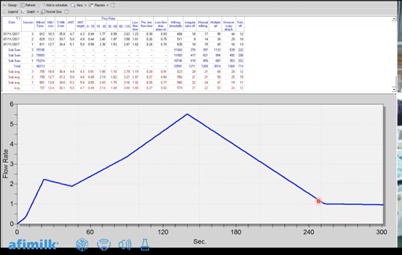

The MPC collects the data described above and sends it to the AfiFarm software milk module where it is displayed in both tabular and graphical form.

Tabular data is useful for when you want to drill down deep into individual parameters, while the graph provides a quick snapshot. With one glance at the milk flow graph, you already have a good idea about whether milk flow in the session was as expected, if there was a problem, and what the problem might be.

To illustrate this further, let’s take a look at the expected versus problematic milk curve.

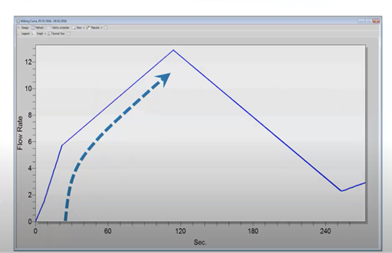

The Expected Milk Curve

The above diagram shows a normal milk flow graph. The blue line depicts the flow. The bottom of the graph shows time in seconds, and the side axis shows the flow rate in Kg/ Min.

As you can see, once the milking cluster is attached, the flow rises steadily, hits a peak, then declines until the end of the session. The rate and consistency of the rise, the time it takes to reach the peak and the total time of the milking session are all important factors. A deviation from the norm on any of the above parameters indicates a problem.

A Problematic Milk Curve

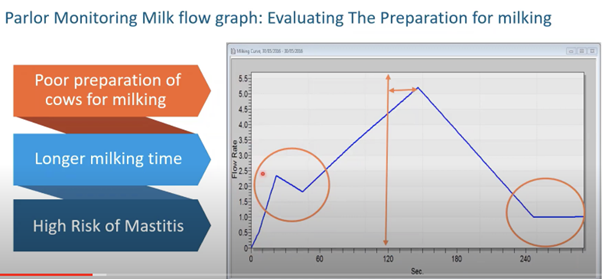

We will now examine an atypical milk flow graph.

The following is a milk graph derived from a milking session on an actual farm. With one look at the milk flow graph, an experienced AfiFarm user will instantly spot several problems with this milking session (indicated on the graph by the orange markings).

Let’s now examine the issues.

- Milking bimodality – At 30 seconds there is a dip in the curve. This dip means that milk flow began, then stopped suddenly, there was a dip in the flow and then flow resumed. This is a common and serious problem in dairy farms in which the milking machine continues to massage the teat for a few seconds in an attempt to extract milk, but no milk comes out. This eventually may lead to teat end damage.

- Late peak – In an ideal scenario, the peak of the milking session should occur at 120 seconds. As you can see on the graph peak in this session occurs around the 150-second mark.

- Low peak – The graph shows that the flow did not reach the expected peak.

- Late take-off – The milking session ends when the flow declines to under 1 kg/min. At this point, the automatic take-off mechanism should kick in and detach the milk clusters as quickly as possible. This graph clearly shows that it took too long for the clusters to detach in this session

Look out for the next blog in this series where you can learn about more KPIs you can track with Afimilk’s milking efficiency module